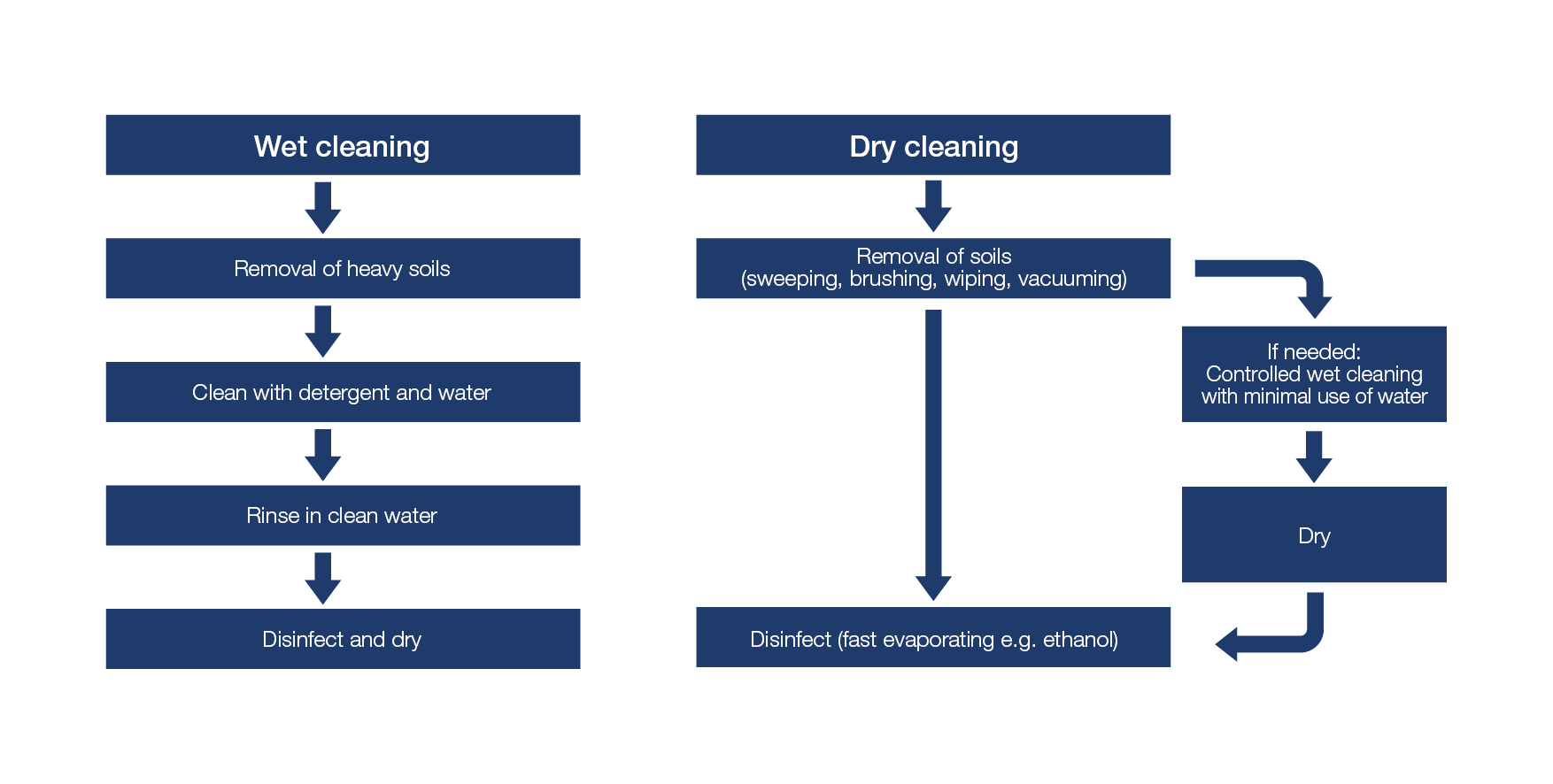

What foods do you associate with Salmonella? Salmonella is one of the leading causes of foodborne illness globally. It is estimated to cause over 90 million cases of diarrhea-related diseases each year. Common symptoms include diarrhea, abdominal cramps, and fever, which usually appear within 12 to 72 hours after consuming contaminated food. The illness typically lasts 2 to 7 days, and most people recover without treatment. However, for vulnerable groups, it can lead to severe complications or even death.  Salmonella is commonly found in the gastrointestinal tracts of animals such as poultry, pigs, cattle, and pets, as well as in insects and humans. It can contaminate soil, water, and food through animal or human feces. Contamination often occurs during food production via raw ingredients, unclean packaging, equipment, or poor hygiene practices by workers. Once inside a facility, Salmonella thrives in warm, moist environments like drains, floors, and processing equipment. While Salmonella is commonly linked to meat, eggs, dairy, and fresh produce, low-moisture foods like infant formula, spices, nuts, peanut butter, flour, and chocolate can also be contaminated. Historically, these foods were not considered high-risk due to their low water activity. However, Salmonella can survive in a wide range of pH levels, temperatures, and moisture conditions, making it capable of persisting in various environments for several months.  1. Prevent Salmonella from Entering the Processing Facility  2. Undertake Proper Cleaning and Disinfection Procedures Cleaning can be categorized into wet cleaning (for meat, vegetables, and dairy) and dry cleaning (for low-moisture foods). Wet cleaning involves using detergents and disinfectants, while dry cleaning avoids water use and requires quick-evaporating disinfectants. In wet cleaning, detergents and disinfectants are used. For dry cleaning, avoid water and ensure disinfectants evaporate quickly. If necessary, perform controlled wet cleaning with minimal water and ensure thorough drying afterward to reduce microbial growth risks. All cleaning procedures should be validated to ensure they work effectively, even under the worst conditions. Regular monitoring through visual checks, ATP testing, or microbial swabs is essential to verify effectiveness. Maintain a detailed cleaning schedule that outlines what, where, when, who, and how to clean. This ensures consistency and accountability in hygiene practices.  3. Implement Salmonella Contamination Prevention Procedures Choose appropriate cleaning methods to avoid spreading contamination. Avoid high-pressure hoses and clean equipment in segregated areas to minimize cross-contamination. When cleaning floors or other surfaces, avoid splashing and aerosolizing contaminants onto food-contact areas. Divide production into zones for raw and processed foods. Use color-coding to distinguish between different hygiene levels, such as raw and processed food zones. Use dedicated, color-coded cleaning tools and food handling equipment. This helps prevent cross-contamination between zones. Storing tools on color-coded wall brackets or shadow boards ensures proper segregation and faster drying, reducing contamination risks.  4. Use Equipment of Good Hygienic Design Select cleaning tools and utensils designed for easy cleaning and to prevent microbial growth. Features such as smooth surfaces, one-piece construction, and no crevices help maintain hygiene. Learn more about hygienic design in this white paper.  5. Monitor Salmonella in the Environment Develop an environmental monitoring program (EMP) to routinely test your production environment for Salmonella. This helps assess hygiene practices, identify potential harborage sites, and mitigate contamination risks. Don’t forget to include cleaning tools in your EMP. Download additional resources on color coding and hygienically designed brushware: Color Coding Guide Cleaning Tool Maintenance White Paper Hygienically Designed Brushware White Paper  One of the great things about working for an organization like Vikan is that I get to support the food industry and advance food safety through many different avenues. I was involved with a Campden... This blog post focuses on how you avoid the worst potential pitfalls of a new color-coding system. Do you know how important the mechanical action applied during cleaning is in removing biofilms? If you don’t already know, you’ll find the answer here. Sofas OUTDOOR,large outdoor sofa,corner garden sofa set,garden sofa set sale Foshan Jianermei Furniture Co., Ltd , https://www.minottiitaly.com

Most likely your answer will be raw meat and eggs, not flour or nuts. However, Salmonella is a very resilient bacterium that can survive in a wide range of food products.

Salmonella in BriefCommon Sources of Salmonella in the Food Industry

Even Low-Moisture Foods Are at Risk of Salmonella Contamination

Five Steps to Control Salmonella in the Food Industry

Want to learn more?

Recent Blog Posts

Updating Campden BRI Guideline 55

Avoid the Color-Coding Pitfalls

Mechanical Action – An Essential Factor in Biofilm Removal

See all posts

Debra Smith - Global Hygiene Specialist

Stine Lønnerup Bislev - Previous Hygiene and Compliance Manager at Vikan

Stine Lønnerup Bislev - Previous Hygiene and Compliance Manager at Vikan